India's #1 Leading Industrial Machin Manufacturer

Menu

Toy Industry

HOME | PHARMA INDUSTRY

10+

Ultrasonic Experienced

Toy Industry

Ultrasonic technology has found various applications in the toy industry due to its versatility and precision. Ultrasonic processes involve the use of high-frequency sound waves to generate mechanical vibrations.

- Plastic Welding: Ultrasonic welding is a common method for joining plastic components in the toy manufacturing process. It works by creating friction between the parts, which generates heat and fuses them together. This is particularly useful for assembling toy parts like action figures, plastic vehicles, and other plastic components.

- Sealing and Cutting: Ultrasonic technology can be used to seal and cut synthetic fabrics, such as those used for stuffed animals and soft toys. The high-frequency vibrations melt the edges of the fabric, creating a strong seam or cutting the material with precision.

- Quality Control: Ultrasonic testing can be employed to assess the structural integrity of toy components. It can help identify defects or weaknesses in materials and manufacturing processes.

- Embossing and Printing: Ultrasonic technology can be used for embossing or printing logos, patterns, or designs onto toy surfaces. This can add decorative elements to toys or provide branding information.

- Inserting Components: Ultrasonic technology can assist in the precise insertion of components such as electronic circuits, batteries, or sensors into toys. This ensures that the components are securely in place.

- Trimming and Finishing: It can be used for trimming excess material or finishing edges on plastic parts, ensuring a polished appearance for toys.

- Packaging: Ultrasonic sealing equipment is used for packaging toys in a secure and tamper-evident manner. This is essential for maintaining product integrity during transportation and on store shelves.

Features

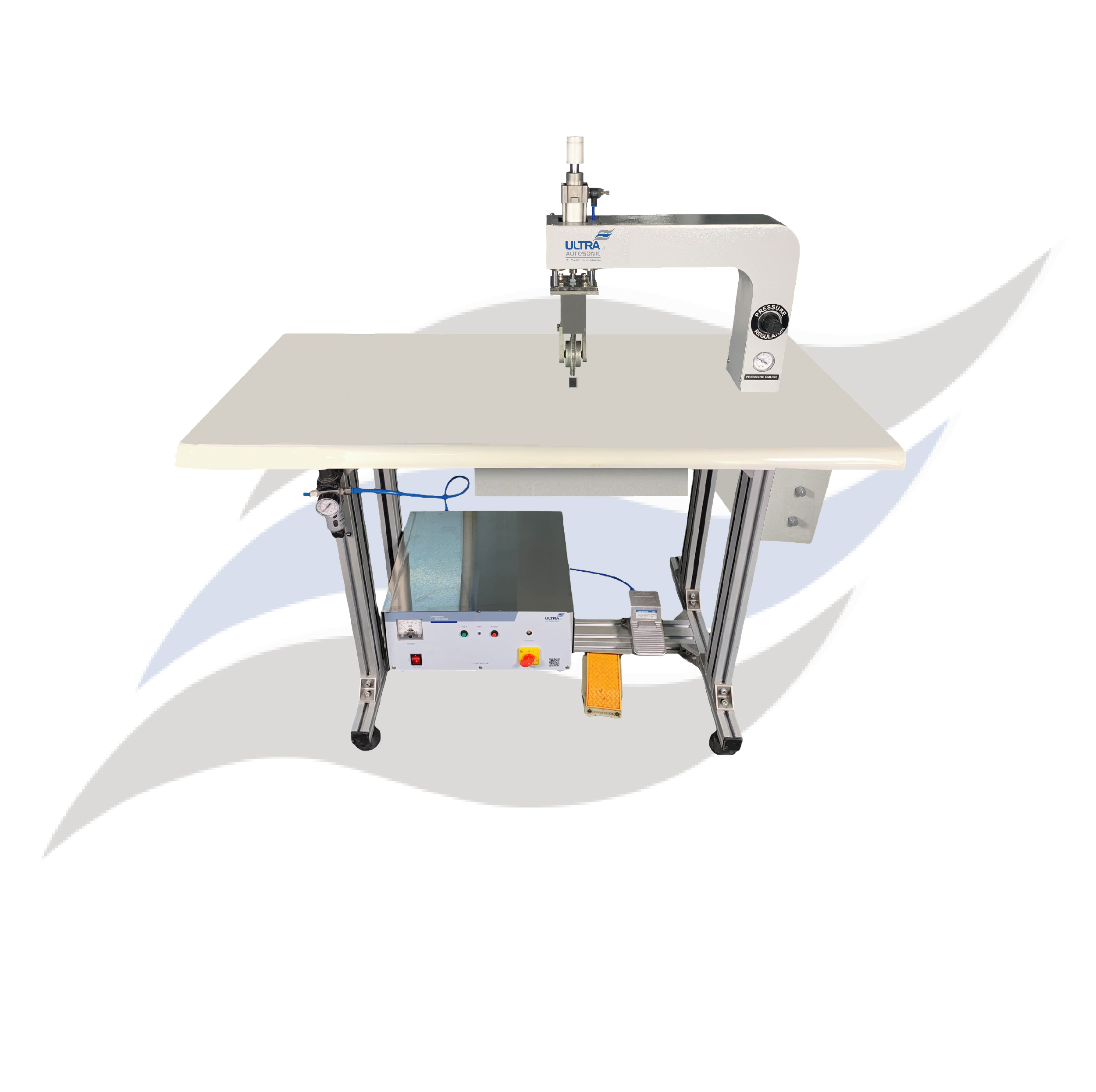

Core Products in Toy Industry

24/7 We Are available

We Are Here For Your Help

All Rights Reserved By Ultrasonic- 2023

Contact Form

Download Brochure

Form submit

Get A Quotation